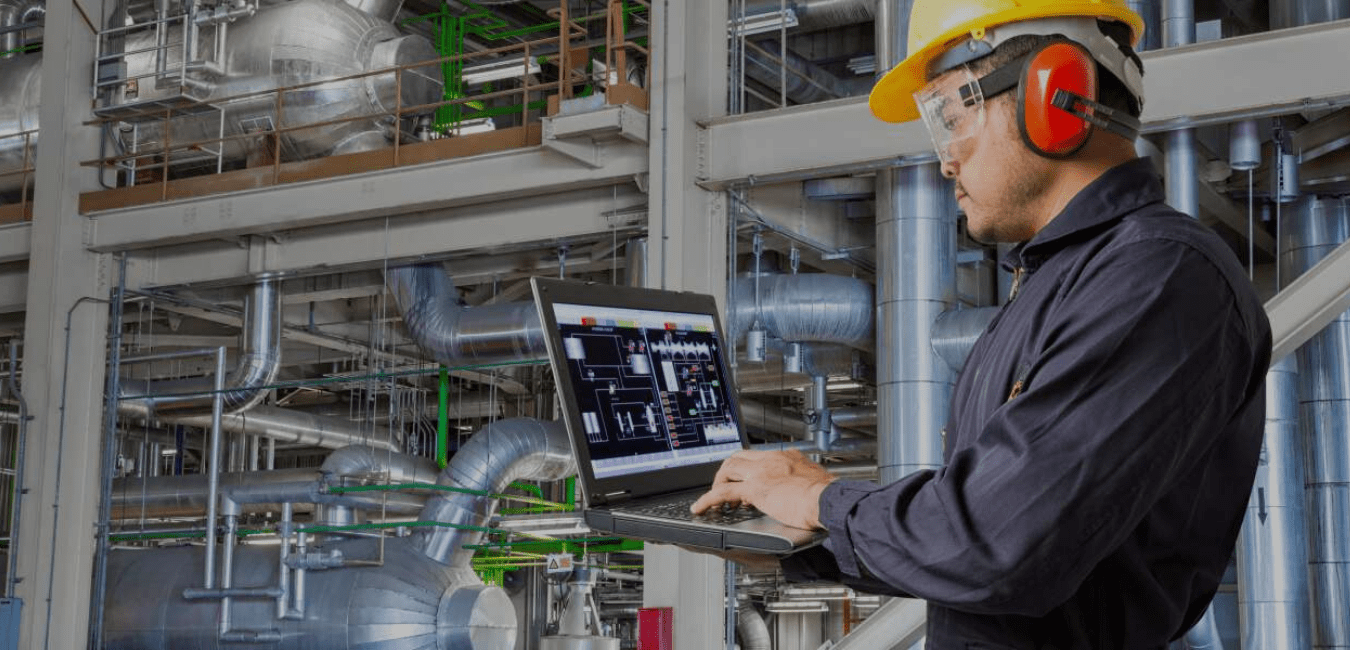

Factory Industrial Automation in Malaysia

PC Group strives to be the control automation system provider that you can rely on quality services and support operations. We can work with you to automate your facility to keep your plant efficiency and increase productivity.

Process Automation

We have successfully completed projects in batch control, recipe management, continuous control, skid control and process functional safety. We offered unparalleled expertise in real-time monitoring and control; and data acquisition. With the extensive experiences in-process controls and instrumentations, we are able to deliver packaged solutions which can vary depending on your needs. We have designed control systems for various applications and industries.

Batch Control Applications

- Vacuum Pan control

- Automated batch blending

- Crystalization

- Chemical Batching

- Wet Process

Skid Control Application

- Air Compressor Skid

- Metering Skid

- Analyzer Skid

Continuous Control Applications

- Spray Dryer

- Evaporator Process

- Pressure Swing Absorbent

- Reformer

- Burner Management System

- Membrane System- Water

- CIP Process

- Pasteurizer

- Facilities Management Control Systems (FMCS)

Process Functional Safety System

The dynamic changes of the industry demand lead us to provide a Safe, Reliable and Efficient system that’s timely and affordable. As a Solution provider of complete process safety systems, we pride ourselves with our Certified TUV SUD Functional Safety Engineers from the industry comply with the Industry standard of IEC61511 in Functional Safety.

ICCS is a combination of functionality for both Control, Safety Systems and other packages. It combined the elements of Process Control Systems and Process Functional Safety System into a single architecture to where safety is critical to the hazardous plant.

As ICSS Engineers with experiences in developing Process Control System and Safety System, they understand the process safety and risk management program implementation requirements and how plants operate because we’ve experienced in these covered processes and facilities. We work with our customers to design Integrated Control and Safety Systems (ICSS) accordingly to their requirements.

Our scope of safety system service covers:

Process Shutdown (PSD)

We designed safety barrier for terminals, refinery and offshore installation to protect the process against safety-related hazard. The production plant will be shut down to prevent any potentially dangerous situation which it will detect hazard that may come from the process or signalled as input from ESD of FGS.

Emergency Shutdown System (ESD)

ESD System is designed for emergency shutdown in terminal, refinery and offshore installation in case any immediate dangerous situations happen or detecting discrepancies in the process. This safety system includes field-mounted sensors, valves, trip relays, system logic for processing of incoming signals, alarm and HMI units.

Modernization of Control System

In the Smart Manufacturing landscape, it is important for a business to gain powerful capabilities to drive competitive advantage. Legacy or out of date control systems can significantly impact your bottom line due to it’s loss of productivity and efficiency. Migration is a cost-effective solution to ensure that your facilities are in good health for sustainability growth. It helps to increased data acquisition and visibility, scalable modular systems and improved plantwide control and optimization

Together, PC Group can partner with you to modernize your control system to improve the plant facilities capabilities and to drive profitability. Our well-experienced engineer is familiar with the modernization program on Siemens S5, Toshiba TOSDIC, Toshiba DPCS /PCS 4000/PCS6000, Simatic TI 505/555/545, Allen Bradley PLC 5, Siemens PCS 6 & below.

Partial Migration

- Replacement of HMI or SCADA

- Replacement of controllers

- Replacement of communication network

- Replacement of field devices

Complete Migration

- New solution of overall system

- Improvise productivity and quality of process

- Expandable communication network and interfacing devices for higher level system like MES or SAP system

Control Panel

PC Group has the capability to design, build, testing, install & commission the right control panel based on your specific requirements. We are able to handle from single operator control stations to the complex custom control panel which follows a stringent quality assurance in assembly, wiring, and testing. Our control panel included the IP rating area classification up to and including Class 1 Div 2 hazardous area.

Our specialist is well experienced with the design and delivery of standard and custom panels for

- PLC Control Panel & Remote IO Panel

- Explosion Proof Panel (EX Panel)

- MCC Panel

- Analyzer Panel

- HMI Panel

- Main Distribution Board

- MIMIC Panel

- Marshalling Panel

- Telemetry Panel

- MCC Capacitor Bank

SCADA Systems Monitoring

Supervisory Control and Data Acquisition (SCADA) systems are an integral part of every control system design. Our solutions enable cost-effective monitoring and remote management of critical equipment in some of the most remote areas. Our system designs are compatible with most of the web browsers and mobile devices. We use industry-standard open protocols such as Modbus RTU/Modbus TCP, OPC DA/OPC UA, DNP3, Ethernet TCP/IP, Profibus PA/ Profibus DP/Profinet, ODBC etc.

A SCADA system linked to perimeter monitoring devices can either significantly reduce or eliminate the need for manned patrols. Unlike patrols, the SCADA system can provide constant monitoring of all locations. Our Scada System able to delivers on the promise of a powerful, intuitive real-time monitoring solution.

We are capable of integrating SCADA & PLC /RTU systems via fiber-optic networks, wireless or telco fixed-line services to meet your needs with monitoring and control devices at some remote location that are to be manned from a central control station such as Substation Control & Monitoring; Gas Distribution Monitoring System; Remote Water Tank Level Control & Monitoring System. As a result, you can take back control of your operations, and harness the value of the process data, increase engineering efficiencies, and simplify your Digital Transformations journey.

Our solutions enable you to:

- Integrate with your existing systems at all sites from a distributed remote environment to the central site.

- Gain full visibility of remote SCADA Systems

- Connect to Remote PLC & RTU

- Reduce Maintenance Costs and Equipment Downtime

- Increase Efficiency and Reduce Site Visits

- Manage change throughout the network, accommodating service and maintenance